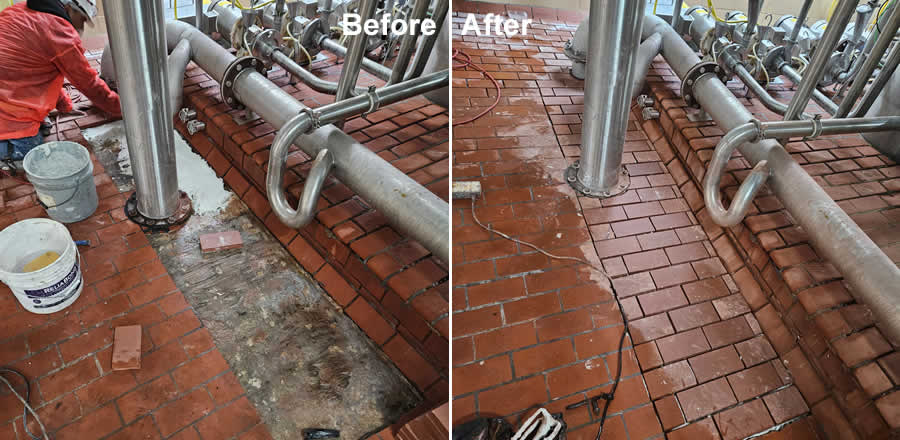

Maintaining the factory floor is a critical aspect of successful industrial operations. Companies like BYCO Inc. in Wisconsin specialize in ensuring that your manufacturing environment remains safe, efficient, and productive. Regular upkeep of flooring systems such as industrial brick and epoxy grout contributes to a well-functioning factory, reducing downtime and ensuring compliance with safety regulations.

Proper factory floor maintenance encompasses a range of services. From conducting thorough floor assessments to implementing repair solutions, it is vital to keep your factory workspace optimized. In this article, we'll explore essential maintenance practices, the importance of assessments, common maintenance materials, and tips for sustaining a durable floor surface.

Regular floor assessments are vital for identifying wear and tear that can lead to safety hazards or operational inefficiencies. Here are some key factors to evaluate:

Performing these evaluations routinely enables proactive solutions rather than reactive repairs, minimizing interruptions in your operations.

After your floor assessment reveals potential issues, a targeted diagnosis follows. Understanding the specific type of flooring—be it vitrified tiles, acid-resistant bricks, or epoxy grout—is essential in deciding on repair methods. Here are common diagnosis and repair practices:

Implementing timely repairs can save long-term costs and ensure compliance with safety standards.

Choosing the right flooring material impacts maintenance strategies. Different materials come with unique properties, advantages, and maintenance needs. Understanding these factors is crucial when selecting flooring solutions for your factory.

Industrial brick flooring is favored for its strength and resistance to heavy equipment. Regularly checking for joint stability and promptly replacing damaged bricks can enhance the longevity of the floor.

Epoxy grout is a popular choice for its moisture and chemical resistance. Regular cleaning and sealing help maintain its effectiveness. It's critical to address any cracks quickly, as moisture can compromise its integrity.

Vitrified tiles are ideal for factory settings due to their hardness and low porosity. Fully vitrified tiles, while more resilient against staining and moisture, often require specific cleaning agents to avoid deterioration. Proper maintenance enhances both types' visual appeal and functionality.

Used mainly in corrosive environments, acid-resistant brick flooring is designed for durability against caustic substances. Regularly checking for integrity and applying appropriate protective coatings can maximize its lifespan and effectiveness.

Emphasizing sustainable practices can significantly reduce long-term costs and downtime. Here are some essential strategies:

Implementing these proactive measures creates a safe and efficient workspace, fostering productivity across your operations.

To maintain an effective factory floor, consider these best practices:

Floor assessments should ideally be performed quarterly for high-traffic areas. However, conducting more frequent inspections in areas with heavy machinery or potential hazards is advisable to ensure immediate remediation of issues.

The best flooring for industrial spaces includes:

Each type has its advantages and maintenance needs, so selecting based on your specific industrial requirements is essential.

To maintain epoxy grout, follow these steps:

Acid brick is specifically designed for environments with corrosive chemicals. It’s not necessary for all industrial settings, so evaluate your operational needs before selecting this flooring type. It’s best suited for areas like chemical plants or food processing facilities.

Common signs that a factory floor requires repair include:

Addressing these signs promptly can prevent more significant issues and safety risks.

Implementing a preventive maintenance strategy can significantly reduce long-term operational costs by minimizing downtime, preventing major repairs, and extending the life of the flooring. Regular attention to maintenance can also enhance workplace safety, indirectly saving costs related to accidents and injuries.

BYCO offers factory floor maintenance services throughout much of Southern Wisconsin. Some of our projects include the cities of Appleton, Ashippun, Beaver Dam, Columbus, Fond Du Lac, Fox Lake, Horicon, Juneau, Madison, Mayville, Menomonee Falls, Milwaukee, Monroe, Muskego, Oak Grove, Oconomowoc, Oshkosh, Watertown, Waukesha, Waupun, West Bend, and surrounding areas in Wisconsin.

If you have more questions about factory floor maintenance or need specialized assistance, contact BYCO Inc. to learn how we can help maintain a safe, efficient workspace for your manufacturing operations.

Implementing a successful maintenance program involves considering various elements unique to your factory environment. Here are key tips for effective factory floor care:

Effective factory floor maintenance is more than just cleaning; it involves regular assessments, targeted repairs, and a solid understanding of various materials. Whether you operate with acrid brick, epoxy grout, or vitrified tiles, ongoing care offers the best return on your investment.

Are you ready to enhance your industrial flooring solutions? Reach out to BYCO Inc. today to explore tailored maintenance programs that fit your manufacturing environment. Together, we can create a safer and more productive factory floor that stands the test of time.

© Copyright BYCO Tile & Floor. All Rights Reserved. Website by Badgerland Marketing.

Contact Information: